Removing-Replacing AC Delco Drilled and Slotted Rotors

First a quick look at what I got:

Each rotor was tagged, "Right Front," Right Rear," etc.

Tools:

Procedure:

- Jack up the front of the car 12" or more and place on jack stands. Note in second picture

the jacking pucks are in place and stands are ready for car to be lowered onto them.

- Remove lug nuts (19mm -100 ft-lbs). I use an impact wrench. If you do it manually

you'll need to loosen them before jacking up the car.

- Pull wheel/tire off.

- Turn steering wheel so you can gain access behind rear of caliper and bracket

(i.e., if you are working on passenger front wheel, turn steering wheel all the way to the left).

- Next remove caliper by loosening the two 15mm caliper bolts found at the rear top and bottom

of the caliper. You'll need a 18mm box end to keep the pin from turning while removing these bolts.

These bolts are only tighten to about 10-15 ft-lbs making removal very easy. A dab of blue

loctite should be used on these upon re-assembly

- Pull caliper off and attach a bungie to top hole in caliper so you can suspend it without

stretching brake line. Then from the top easily pull the brake pads away from the brake pad

bracket (black). I replaced them exactly how they came off so they continued to wear and rub the

new rotor in the same direction they did on the rotors I was removing.

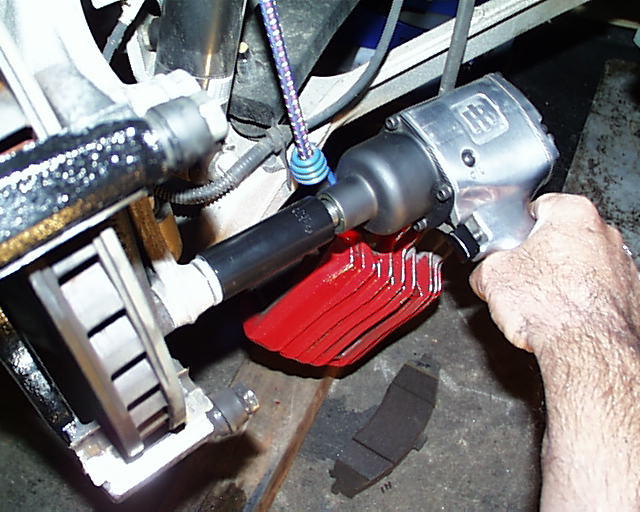

- Next remove the two 21mm bracket bolts securing the black bracket. These have

red loctite on them and are torqued to 125 ft-lbs. The impact wrench

handles them with ease. (You might notice that I'm using a 21mm long socket

on the impact wrench. This IS NOT NECESSARY. It was the only 21mm socket I had.)

- Once the 21mm bracket bolts are removed the bracket will fall into your hands.

Good time to clean and paint it.

- Liberally squirt some WD-40 around the hub and on the two set washers that

hold the rotor in place. Wait 30 seconds or so and repeat. Continue to repeat as necessary.

You won't hurt a thing other than

see a puddle forming on the garage floor.

- Using a knife blade or tiny screwdriver tip start wedging those washers

away from the rotor. Its possible to work them out far enough where you

can spin them off. They are only found on the front rotors.

- Remove rotor. Sounds easy enough but it might be rusted to hub so use

WD-40 liberally. A rubber mallet might help. Keep striking the back of

the rotor while turning it until it breaks free. Be careful not to hit

any wiring. Depending on how hard you hit the rotors, they should break free after fifteen to

twenty average whacks. Some people don't like this method because they see the potential of damaging

the rotors. I say, so what? You are replacing them! Besides, I doubt you can hit them hard enough to

cause any distortion.

- I painted the inner area (called the hats) where the pads WON'T TOUCH using hi-temp clearcoat to keep the original

finish visible and protected from rusting. Won't know for a long time how that'll hold up as I live in

San Diego. I did this project in May 2005. We won't see rain again for about six months from now.

- This is the paint I used, bought at Pep Boys. They had a brand/type that resists higher temperatures but it required curing in a 600 degree

oven so I passed on it. So far (3 yrs. later-2/08) I haven't seen any signs of peeling or discoloring (ie. still looks good as new). I have yet to drive

in wet conditions so I can't comment on rust.

- Here's the finished product (Front & Rear):

Don't forget to dab some blue Locktite on the caliper bolt threads and red Loctite onto the last four threads near the bolt head of those

21mm bracket bolts before their reinstallation.

What I did to insure perfect alignment of the brake pad bracket before tightening the 21mm bolts was to

put the bracket in place then hand thread both bolts on to hold the bracket securely. Then I removed

the top bolt, applied two dabs of red Loctite (it takes

about 20 minutes to dry) to its upper threads, re-fastened the bolt as tight as I could with a

standard socket wrench, then used the torque wrench to finish the job.

Next I removed the bottom bolt and repeated the process.

Also, applying a little tiny bit of anti-seize to the bolt threads the lugnuts spin onto might make

the lugnut removal easier next time. They will be torqued down to 100 ft-lbs. so you shouldn't worry

they'll come loose because of the anti-seize. I should add, some people find doing this

not a good idea. You decide for yourself. I find it keeps the threads from rusting and corroding.

The rear procedure isn't much different.

Because I have painted calipers. I found they chipped easily if they touched any of the

suspension arms etc. so I ended up wrapping them in a small towel after unbolting them.

I jacked the rear of the car up higher (rear jack stands were extended to 14") than the front

while leaving the front on the jack stands. The reason you need the rear higher is you'll need

some extra space to use the torque wrench on the rear brake pad bracket bolts.

If, when you began this project, you

rolled your front wheels onto 2x4's or some something to get your jack under the front cross-member,

be sure to remove those blocks from under the front wheels if you've re-installed them at this point.

Else you might find the front wheels will come down on the blocks while you are jacking up the rear

causing them lift the front of the car off the front jack stands. This potentially might cause your

car to roll forward. That might end up being a little ugly so be careful.

Also, if you have an 6-speed, once you've got the rear jacked up, take it out of gear and release

the e-brake or you'll NEVER pull the rear rotors off.

Generally, the rear rotors will require more banging than the fronts because you must overcome

the resistance of the e-brake shoes on the rear rotors. Persistence is the key word here.

Keep swingin'!

SAFETY POINT: After you've finished the rear, Before you lower the rear of the car,

be sure you put the tranny

back in gear and re-apply the e-brake. I wrote myself a note and taped it to my jack

handle so I wouldn't forget. (You really don't want your vette to roll away from you when

you lower the front after lowering the back.)

General observation. I didn't realize how easy it is to change brake pads.

Being interested in doing some autocrossing in the future and reading

suggestions about changing pads for racing I thought, "What a pain in

the a$$ that must be but I was wrong! It's so easy. And, if you have autocross

wheels/tires as well it barely adds a minute or so when swapping your stock tires for your autocross

tires.

Good luck!